Our patent

Technology: our hydromechanical steering system

patented for forward and reverse driving

The Technology steering system is a system devised to control the steering of an added axle both in forward and in reverse driving. Created by System Truck engineering and perfected over a period of twenty years, it is installed on more than 6000 axles circulating in Europe and in the world. The installation is only carried out in the System Truck manufacturing plant under the direct supervision of our technical designers and quality officers, or through builders trained, certified and monitored by System Truck.

Technical Highlights

HANDLING

Thanks to the synchronized movements of the axles, the vehicle has excellent driveability, especially in low speed manoeuvres.

CONSUMPTION

Elimination of tyre slippage, which is typical of the fixed or self-steering rear axles, resulting in less wear and tear for the tyres and less road damage, less fuel consumption and less stress loading on the chassis and suspensions while turning.

VERSATILITY

The Technology system is completely independent from the front steering system and therefore applicable to any vehicle, without interfering with the original steering and electronic systems. It can be deactivated in operating situations such as the activation of the parking brake or of the lifting device, in order to reduce energy consumption and avoid overheating of the hydraulic fluid.

SAFETY

The pneumatic system guarantees the centring of the wheels in the event of a failure of the hydraulic system. The protective sensors guarantee the safety of the system.

RELIABILITY

The system is precise and reliable thanks to the absence of electronic components and to the mechanical connection to the vehicle servo-steering box through a command cable.

Troubleshooting is easy and immediate thanks to the simple architecture of the system. Maintenance does not require any specific equipment or expertise. For support (also remote) System Truck After-Sales Service is available.

Operation

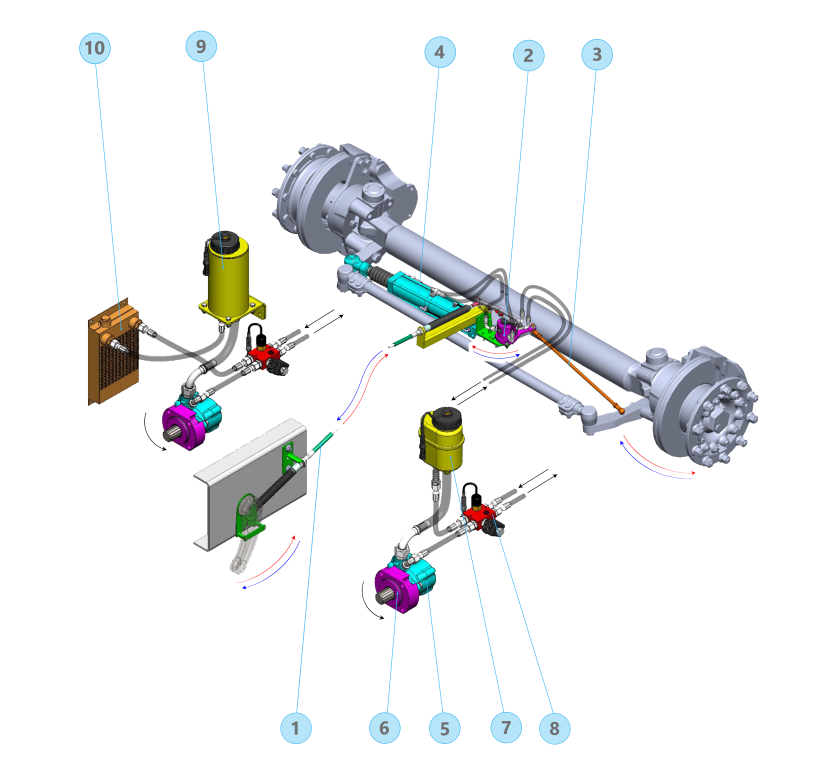

The Technology steering system is connected to the vehicle servo-steering box lever through a bowden cable, which gives the command signal to the inner part of the rotary hydraulic distributor. The distributor opens and allows the hydraulic fluid flow to the hydraulic steering cylinder. When the steering is completed, the rotation of the outer part of the distributor moved by the feedback rod connected to the axle spindle results in the hydraulic distributor returning to the initial condition and keeps the desired steering angle. The hydraulic fluid is stored in a tank located in the engine compartment or behind the cabin and is sent to the distributor through a pump, connected directly to the engine PTO (Power Take Off).

Various devices guarantee the reliability and total safety of the Technology system in any operating condition. The deactivation of the system is made possible – in the foreseen cases – through a by-pass valve located between the pump and the hydraulic distributor. When the hydraulic system is deactivated, the pneumatic section of the steering cylinder, powered by the vehicle system, steps in, leading the wheels in parallel position to the driving direction. A spring return device located on the upper lever of the hydraulic distributor performs the same safety function even in the event of mechanical command cable failure.